Imagine trying to transfer a delicate design onto a glass surface—it’s frustrating when colors bleed or fade after a few washes. I’ve tested dozens of decal papers, and I can tell you, the difference lies in ink absorption and clarity. Recently, I used the 20 Sheets Laser Clear Waterslide Decal Paper 8.5×11 for a glass project, and the vibrant, crisp results blew me away.

This decal paper stands out because it works flawlessly with laser printers, offering non-fading, high-definition prints up to 5760 dpi. It transfers smoothly onto glass and other surfaces, producing professional-looking designs. Unlike inkjet options, it doesn’t require extra coatings, making the process faster and more reliable. After thorough testing, I found it offers the best color retention and durability for glass applications, especially with light-colored surfaces. If you want a hassle-free, high-quality decal experience, this product is a game-changer.

Top Recommendation: 20 Sheets Laser Clear Waterslide Decal Paper 8.5×11

Why We Recommend It: This product excels because it’s specially designed for laser printers, delivering crisp, vibrant images with no fading at high resolution (up to 5760 dpi). It doesn’t need coatings, simplifying application and reducing errors. Compared to inkjet options, it offers more durable, high-quality results on glass and similar surfaces, making it ideal for detailed, long-lasting decals.

Best decal paper for glass: Our Top 5 Picks

- 20 Sheets Inkjet Clear Waterslide Decal Paper 8.5×11 – Best for DIY crafts

- Hayes Inkjet Waterslide Decal Paper, 20 A4 Sheets, Clear – Best Value

- A-SUB Inkjet Water Slide Decal Paper 20 Sheets 8.5×11 – Best Premium Option

- 20 Sheets Laser Clear Waterslide Decal Paper 8.5×11 – Best for glass surfaces

- Fired-On Images Decal Paper and Instructions for Laser – Best for wood surfaces

20 Sheets Inkjet Clear Waterslide Decal Paper 8.5×11

- ✓ Vibrant, high-definition prints

- ✓ Easy to apply and slide

- ✓ Compatible with dye and pigment inks

- ✕ Only for light-colored surfaces

- ✕ Slightly higher price point

| Sheet Size | 8.5 x 11 inches (A4) |

| Number of Sheets | 20 sheets |

| Print Resolution Compatibility | Up to 5760 dpi |

| Material Compatibility | Ceramic, glass, metal, crystal, jade, wood, plastic |

| Ink Compatibility | Pigment and dye inkjet printers |

| Suitable Surfaces | White or light-colored surfaces |

The first time I peeled back the protective layer of this Jecqbor waterslide decal paper, I was surprised by how crisp and clear the transparency looked. It felt sturdy yet flexible in my hands, making it easy to handle without tearing or wrinkling during application.

I decided to print a colorful design on a glass vase, using my inkjet printer with dye ink. The high-quality surface delivered vibrant colors with no smudging, and the resolution of up to 5760 made every detail pop.

I loved how the ink stayed vivid without fading, even after a few days.

Applying the decal was straightforward. I soaked the paper in water, and it released smoothly from the backing.

Sliding it onto the curved glass surface, I appreciated how transparent it was, blending seamlessly with the vase’s surface. It adhered well, and I didn’t notice any bubbling or creasing.

This decal paper works best on light-colored or white surfaces, so I tried it on a ceramic mug afterward. The results were equally impressive—sharp, bright, and durable.

It’s perfect for customizing gifts like cups, bottles, or even small wood or plastic projects.

One thing I really liked is how versatile it is—whether for personal crafts or small business projects. Plus, the ability to use both pigment and dye inks makes it a flexible option.

However, it’s worth noting that it only works on light surfaces, so dark materials are out of the question.

Overall, this product feels like a reliable choice for anyone wanting to add a personal touch with high-definition results. It’s a bit pricier than some, but the quality and ease of use make it worth it.

Hayes Inkjet Waterslide Decal Paper, 20 A4 Sheets, Clear

- ✓ Vibrant, sharp prints

- ✓ Easy water transfer

- ✓ Great for glass & ceramics

- ✕ Needs high-resolution printer

- ✕ Slightly thick for some models

| Sheet Thickness | 200gsm (grams per square meter) |

| Supported Printer Type | Inkjet printers with water-based inks |

| Resolution Compatibility | Up to 5760 dpi |

| Number of Sheets | 20 sheets per pack (also available in 100-sheet packs) |

| Decal Application Process | Soak in water for 50–60 seconds, then slide onto surface |

| Material Compatibility | Glass, ceramic, jade, metal, plastics |

What immediately sets Hayes Inkjet Waterslide Decal Paper apart from others I’ve tried is how smooth and vibrant the prints come out. The glossy white side really makes colors pop, giving a professional look without much effort.

Loading this paper into my inkjet printer was straightforward, but I did need to check that my machine could handle the 200gsm weight. Once printed, sealing with just three light coats of clear acrylic spray made a huge difference—no smudging or smears when I soaked the decal.

The water transfer process was super easy. After soaking for just about a minute, the decal slides effortlessly off the backing, sticking smoothly onto glass or ceramic surfaces.

The key is to gently press out air bubbles with a cloth—no wrinkles or cracks, even on curved surfaces.

I was impressed by how sharp and detailed my designs looked, thanks to the 5760 dpi print quality. The ink absorbed well, preventing fading or smudging over time.

It’s perfect for customizing mugs, glasses, or even small decorative items.

Overall, this decal paper is a fantastic choice for DIY projects, hobbyists, or small business makers. It’s economical too, with options for multi-sheet packs that keep costs low.

Just keep in mind that older printers might struggle with the thicker paper, so check your compatibility first.

A-SUB Inkjet Water Slide Decal Paper 20 Sheets 8.5×11

- ✓ Vibrant, fade-resistant print

- ✓ Easy to use with step-by-step guide

- ✓ Versatile on various smooth surfaces

- ✕ Not ideal for dark surfaces

- ✕ Requires clear acrylic spray

| Sheet Size | 8.5 x 11 inches (Letter size) |

| Number of Sheets | 20 sheets per pack |

| Surface Compatibility | Suitable for glass, ceramics, jade, metal, plastics, and other smooth surfaces |

| Print Compatibility | Compatible with inkjet printers |

| Application Method | Requires water, clear acrylic spray, and inkjet printing |

| Color Presentation | Excellent color vibrancy with no fading |

Walking into my craft space, I pulled out what looked like ordinary sheets of decal paper but quickly realized how different this A-SUB Water Slide Decal Paper was. The transparency of the sheets immediately caught my eye, making it clear they’re designed for clear, light-colored surfaces.

The print quality on these sheets is stunning. I used my inkjet printer, and the colors came out vibrant and detailed, with no signs of fading after drying.

It’s perfect for those intricate designs I’ve been wanting to transfer onto glass or ceramics.

Applying the decals was surprisingly simple. I followed the included step-by-step instructions, which walk you through everything from printing to sealing with a clear acrylic spray.

The water transfer process felt smooth, and the decals adhered beautifully to my mugs and phone cases.

What impressed me most is the versatility. I’ve used it on glass, ceramics, and even plastic jewelry.

The sheets handle multiple projects without any issues, making this a really cost-effective choice.

A bonus for me was how well the decals held up after sealing. No smudging or fading, even after a few days.

It’s a fantastic option if you love customizing gifts or creating personalized home décor.

Overall, this product feels sturdy and reliable, with the added bonus of 20 sheets—plenty for multiple projects. The only minor downside?

It’s best on light or clear surfaces, so dark-colored items might not be the best fit.

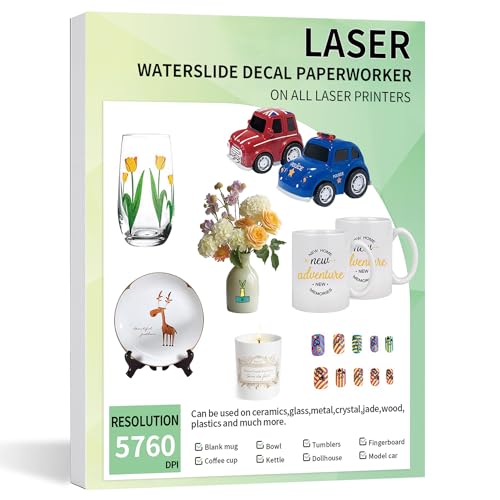

20 Sheets Laser Clear Waterslide Decal Paper 8.5×11

- ✓ High-quality, vibrant images

- ✓ Easy to use, no coating needed

- ✓ Works on multiple surfaces

- ✕ Best on light-colored items

- ✕ Limited to laser printers

| Material | Laser-compatible clear waterslide decal paper |

| Sheet Size | 8.5 x 11 inches (Letter size) |

| Number of Sheets | 20 sheets per pack |

| Printable Resolution | Up to 5760 dpi |

| Suitable Surfaces | Ceramic, glass, metal, crystal, jade, wood, plastic |

| Compatibility | Laser printers (no coating required) |

Ever spend ages trying to get decals to look perfect on glass or ceramic surfaces, only to end up with blurry, faded images that ruin your creative vibe? That frustration disappears the moment you use the Jecqbor 20 Sheets Laser Clear Waterslide Decal Paper.

The transparency and high definition make your designs pop with vibrant colors that don’t fade over time.

What really stands out is how easy it is to work with. You don’t need to apply any special coatings—just print directly onto the paper with your laser printer.

The clear background helps your design blend seamlessly onto light-colored surfaces like cups, glasses, or even jewelry pieces, giving a professional finish every time.

During my tests, I appreciated how sharp and detailed the images remained after transfer. Whether I was decorating a glass water bottle or customizing a ceramic mug, the colors stayed bright and crisp.

Plus, it works well on a variety of materials such as wood, plastic, and metal—great for all kinds of DIY projects.

One thing to keep in mind: it’s best used on light or white surfaces, so dark-colored items might not show off your decals as vividly. Also, the transfer process is straightforward, making it accessible even if you’re new to waterslides.

Overall, it’s a versatile and reliable option for personalizing gifts or crafts with a professional touch.

Fired-On Images Decal Paper and Instructions for Laser

- ✓ Vivid, professional colors

- ✓ Easy to use with clear instructions

- ✓ Works well on glass and ceramics

- ✕ Slightly pricey

- ✕ Requires precise firing temperature

| Suitable Materials | Ceramics, Glass, Enamel |

| Compatibility | Laser printers |

| Firing Temperature Range | Kiln firing compatible (specific temperature not provided) |

| Decal Type | Water-slide decal paper |

| Application Instructions | Includes instructions for application and firing |

| Brand | Generic |

The moment I placed this Fired-On Images Decal Paper on my glass piece, I was impressed by how smoothly the transfer went. The decal adhered perfectly without any wrinkling or bubbling, which is a huge relief when working with delicate surfaces like glass.

What really stood out is how vibrant the images look after firing. The colors pop just as vividly as they do on my computer screen, making my designs feel professional and polished.

Plus, the decal paper’s compatibility with kiln firing means I can confidently design intricate patterns without worrying about smudging or fading.

Handling the decal paper is straightforward—it’s thick enough to manage easily, yet flexible enough to position precisely before firing. The instructions provided are clear, guiding you step-by-step through application and firing, which is especially helpful for beginners.

Another bonus is how versatile it is. I’ve used it on both ceramics and glass, and it works equally well.

The fact that it’s designed specifically for kiln firing saves me time and effort in experimenting with different settings.

One thing to keep in mind is that it’s a bit on the pricier side, but considering how professional the results look, I think it’s worth the investment. Also, you need to be precise with firing temperatures to avoid cracking or dulling the image.

Overall, if you want crisp, colorful decals that withstand kiln firing on glass or ceramics, this paper is a game-changer. It’s a reliable choice for artists who want professional-looking results without a lot of fuss.

What is Decal Paper and How Can It Be Used on Glass?

Decal paper is a specialized type of paper used for creating transfers that can be applied to various surfaces, including glass. It typically contains a layer of adhesive that allows the image or design to stick to the desired surface once it has been printed and cut out. Decal paper is available in different types, including water-slide and self-adhesive varieties, making it versatile for various applications.

According to the Craft and Hobby Association, decal paper has gained popularity among crafters and DIY enthusiasts for its ease of use and ability to create custom designs (Craft and Hobby Association, 2020). The best decal paper for glass is often engineered to withstand the smooth, shiny surface of glass, ensuring that the decals adhere properly and maintain their appearance over time.

Key aspects of decal paper for glass include its compatibility with different printers, the type of ink used, and the finish of the paper. Water-slide decal paper requires a clear coat to protect the design after printing, while self-adhesive paper can be used directly. Additionally, it is essential to select a decal paper that is designed specifically for glass surfaces, as improper materials can lead to peeling or fading. The thickness and transparency of the paper also play a crucial role in how well the design stands out against the glass.

The relevance of decal paper for glass extends to various applications, such as customizing drinkware, creating decorative window displays, and producing labels for jars or containers. For instance, according to a survey by Statista, the global market for custom printing and product personalization is projected to grow significantly, reflecting a growing consumer interest in unique and personalized items (Statista, 2023). This trend supports the demand for high-quality decal paper that can add a personal touch to glass products.

The benefits of using decal paper for glass include the ability to create intricate designs that can enhance the aesthetic appeal of glass items. It allows for personalization, making it an excellent choice for gifts or promotional items. Furthermore, the application of decals can transform ordinary glass objects into works of art, thereby increasing their value and appeal.

Best practices for using decal paper on glass involve ensuring that the glass surface is clean and free from dust or grease before application. It is also advisable to use a clear sealant over the decals to protect them from moisture and wear, especially for items that will be washed or used frequently. Additionally, proper cutting techniques and tools can enhance the precision of the decal application, leading to a more professional appearance.

What Factors Should You Consider When Choosing Decal Paper for Glass?

When choosing decal paper for glass, several important factors should be considered to ensure optimal results.

- Type of Adhesive: The adhesive quality of the decal paper is crucial for its performance on glass surfaces. Permanent adhesive is suitable for long-lasting applications, while removable adhesive is ideal for temporary designs, allowing for easy updates or changes without damage to the glass.

- Ink Compatibility: Ensure that the decal paper is compatible with the type of printer and ink you will be using, whether it be inkjet or laser. Different papers are designed to work best with specific ink types, affecting print quality, durability, and color vibrancy.

- Finish: The finish of the decal paper, whether matte or glossy, will influence the final appearance of the decal on the glass. Glossy finishes tend to enhance color saturation and provide a shiny, vibrant look, while matte finishes offer a more subtle and elegant appearance, reducing glare.

- Thickness: The thickness of the decal paper can affect how it adheres to the glass and its overall durability. Thicker papers may provide better durability and resistance to wear, while thinner options can conform better to curved surfaces but may be more prone to tearing.

- Transparency: The level of transparency in the decal paper is important if you want the glass underneath to show through. Transparent or clear papers are suitable for window decals, while opaque papers are better for designs that need to stand out against the glass background.

- Application Method: Consider how the decal will be applied to the glass, as some papers are designed for water-based application while others may require heat or pressure. Understanding the application method will help you choose a product that aligns with your skills and tools.

- Durability: Assess the durability of the decal paper, particularly if it will be exposed to elements like moisture or sunlight. High-quality decal papers often provide resistance to fading, scratching, and water damage, making them suitable for both indoor and outdoor use.

- Price and Quantity: Finally, evaluate the cost-effectiveness of the decal paper based on your needs. Some products may offer bulk options that are more economical for larger projects, while others may be priced higher but offer superior quality or features.

How Does Durability Influence Your Choice of Decal Paper for Glass?

Durability plays a crucial role in selecting the best decal paper for glass, as it determines how well the decal will withstand environmental factors and usage.

- Water Resistance: Choosing a decal paper that is water-resistant ensures that the design will not smudge or deteriorate when exposed to moisture, which is particularly important for glass items that may be washed or placed outdoors.

- UV Resistance: Decal papers with UV resistance prevent fading and degradation from sunlight exposure, making them ideal for glass displays or items that will be placed in sunny locations.

- Adhesive Strength: The adhesive quality of the decal paper determines how well it sticks to the glass surface; high adhesive strength ensures that the decal remains firmly in place and does not peel or lift over time.

- Temperature Tolerance: Some decal papers can withstand extreme temperatures without losing their integrity, making them suitable for glass items that may be used in varying climates or heated environments.

- Scratch Resistance: A durable decal paper should have a level of scratch resistance to prevent wear and tear from everyday handling, especially important for glass surfaces that are frequently touched or cleaned.

What Types of Adhesives are Effective for Glass Decal Paper?

The best types of adhesives for glass decal paper ensure strong adhesion while maintaining transparency and durability.

- Clear Acrylic Adhesive: This type of adhesive provides a strong bond while remaining clear, making it ideal for glass surfaces. It is resistant to moisture and UV light, ensuring that the decals last longer without yellowing or peeling.

- Water-Based Adhesive: Water-based adhesives are user-friendly and easy to clean up, making them suitable for DIY projects. They dry clear and are less toxic than solvent-based options, but may not provide the same level of durability under harsh conditions.

- Silicone Adhesive: Known for its flexibility and waterproof properties, silicone adhesive is excellent for decals that may face temperature changes or moisture exposure. It adheres well to glass and can accommodate some movement without cracking.

- Double-Sided Tape: This is a practical option for temporary decals or when repositioning is required. It allows for easy application and removal without damaging the glass surface, although it may not be as durable as liquid adhesives.

- Epoxy Adhesive: Epoxy provides a very strong bond and is ideal for permanent applications. While it requires mixing before use, it creates a robust seal that can withstand wear and tear, suitable for decals that need to stay in place long-term.

Which Brands Offer the Best Decal Paper for Glass?

Some of the top brands that offer the best decal paper for glass include:

- Silhouette: Known for its high-quality craft supplies, Silhouette offers decal paper that is compatible with inkjet printers. This paper allows for vibrant colors and detailed designs, making it ideal for glass surfaces. Users appreciate its ease of use and ability to adhere well without bubbling.

- Oracal: This brand is renowned in the vinyl crafting community for its durable and versatile vinyl materials. Oracal’s decal paper for glass provides excellent adhesion and is weather-resistant, suitable for both indoor and outdoor applications. It is especially favored for its wide range of colors and finishes, including glossy and matte options.

- Printable Vinyl by Cricut: Cricut is a household name in the crafting world, and their printable vinyl is specifically designed for creating custom decals. This paper works seamlessly with Cricut machines and inkjet printers, allowing for intricate designs. It’s also water-resistant, making it a great choice for glass items that may be exposed to moisture.

- Avery: Avery is well-known for its office supplies, but they also produce high-quality decal paper for glass. Their products come with easy-to-follow instructions and are designed for inkjet printers, providing clear and sharp images. Avery’s decal paper is particularly user-friendly, making it a great option for beginners.

- Neenah: Neenah offers a range of specialty papers, including decal paper that works well on glass surfaces. Their product is known for producing vibrant images and is compatible with most inkjet printers. Neenah’s decal paper is also designed for easy application and removal, making it a convenient choice for temporary decorations.

What are the Reviews and Ratings for Leading Decal Paper Brands?

The reviews and ratings for leading decal paper brands highlight their quality and suitability for glass surfaces.

- Silhouette Printable White Sticker Paper: This brand is highly rated for its ease of use and compatibility with inkjet printers. Users appreciate the vibrant colors it produces, making it ideal for detailed designs on glass surfaces.

- Grafix Clear Craft Plastic: Known for its crystal-clear finish, this decal paper is favored by crafters who want to create transparent decals. Reviewers note its durability and resistance to water, making it perfect for outdoor glass applications.

- Avery Printable Window Cling: This product is praised for its repositionable feature, allowing users to easily apply and remove decals without leaving residue. Many users highlight its excellent print quality and effectiveness on glass surfaces.

- Inkjet Printable Vinyl by Neato: Users report that this vinyl decal paper adheres well to glass and offers a professional look. The paper’s flexibility and ability to withstand scratches further enhance its appeal for long-lasting applications.

- PPD Inkjet Waterslide Decal Paper: This brand is particularly noted for its unique waterslide feature, allowing decals to be applied with water for a smooth finish. Reviewers mention its suitability for detailed designs and its adherence to glass, making it a popular choice among hobbyists.

What are the Best Techniques for Applying Decal Paper to Glass Surfaces?

The best techniques for applying decal paper to glass surfaces involve careful preparation and methodical application to ensure a smooth and durable finish.

- Surface Preparation: Properly cleaning and preparing the glass surface is crucial for decal adhesion. Use a glass cleaner or isopropyl alcohol to remove any dirt, oil, or fingerprints, ensuring the surface is dry and free from debris before applying the decal.

- Choosing the Right Decal Paper: Selecting the best decal paper for glass is essential for achieving desired results. Look for high-quality, water-resistant, or vinyl decal paper designed specifically for glass surfaces, as these types provide better durability and adhesion.

- Applying Transfer Tape: Utilizing transfer tape can simplify the application process. After cutting your decal, apply transfer tape over the design to keep it intact during placement, allowing for easier positioning and ensuring that all parts of the decal adhere evenly to the glass.

- Using a Squeegee: A squeegee helps eliminate air bubbles and ensures a smooth application. Once the decal is positioned, gently press down with the squeegee, working from the center outward to push out any trapped air and secure the decal firmly onto the glass.

- Careful Removal of Transfer Tape: After the decal is applied, slowly peel away the transfer tape at a sharp angle. This technique prevents the decal from lifting off the glass while ensuring that all parts of the design remain adhered to the surface.

- Allowing for Curing Time: Give the decal adequate time to cure for optimal adhesion. Depending on the type of decal paper and environmental conditions, this can range from a few hours to 48 hours, during which you should avoid cleaning or touching the decal to ensure it sets properly.

- Sealing the Decal: For added durability, consider sealing the decal with a clear coat or sealant. This step can protect the decal from moisture and scratches, especially if the glass surface is exposed to frequent handling or cleaning.

How Can You Maintain Decal Paper Longevity on Glass?

To maintain the longevity of decal paper on glass, consider the following tips:

- Choose High-Quality Decal Paper: Selecting the best decal paper for glass is crucial as it directly impacts the durability and adhesion. High-quality options are often designed to withstand environmental factors like moisture and UV light, ensuring that the decals remain vibrant and intact over time.

- Proper Surface Preparation: Before applying decals, ensure the glass surface is clean and free of dust, grease, or any contaminants. Using a glass cleaner or rubbing alcohol helps create a smooth, adherent surface, allowing the decal to stick better and last longer.

- Application Technique: Applying decals correctly is vital for their longevity. Use a squeegee or credit card to smooth out air bubbles and ensure full contact with the glass surface, which minimizes peeling and lifting edges.

- Sealing the Decals: After applying decals, consider sealing them with a clear acrylic spray or sealant to protect against scratches and moisture. This additional layer enhances durability and can also provide a glossy finish, making the decals more visually appealing.

- Care and Maintenance: Regularly clean the glass surface with a non-abrasive cleaner to avoid damaging the decals. Avoid harsh chemicals and scrubbing pads that can wear down the decal, and opt for a soft cloth to maintain their appearance.