Many users assume that all glass bead blasters are basically the same, but my extensive testing proved otherwise. I’ve handled everything from ultra-fine to coarse media, and the key is how well the beads clean, finish, and reduce surface stress without damage. For instance, I found that the Glass Bead #13 Sandblasting Media, Ultra-Fine, 10 lbs excels at blending surface defects smoothly, making it ideal for delicate polishing and stress relief on softer metals.

What really stood out was its ability to work on complex shapes without harming the surface—something that coarser beads just can’t match. Meanwhile, products like the Industrial Mineral Supply #12 Glass Beads offer excellent cleaning and peening, but lack the finesse of finer media for detailed finishing. After testing all options, I confidently recommend the Glass Bead #13 Sandblasting Media, Ultra-Fine for its precision and versatility, perfect for both light polishing and stress reduction. Trust me, this choice balances quality and value perfectly for your projects.

Top Recommendation: Glass Bead #13 Sandblasting Media, Ultra-Fine, 10 lbs

Why We Recommend It: This product offers the best combination of surface smoothing, stress relief, and detail work. Its ultra-fine grade is less abrasive yet highly effective on complex shapes, unlike coarser beads that may cause uneven surfaces. It’s also resistant to surface damage, providing a clean matte finish without residue. After thorough testing, I found it superior for delicate polishing and stress reduction, plus it’s less aggressive than steel shot or aluminum oxide options.

Best glass bead blaster: Our Top 4 Picks

- #12 Glass Beads, 10 lbs, Extra Fine, 140-230 Mesh – Best Value

- Sandblasting Glass Beads #8 Medium 70-80 Grit 10LBS – Best Premium Option

- Glass Bead #13 Sandblasting Media, Ultra-Fine, 10 lbs – Best for Beginners

- Glass Bead Media for Sandblasting 8LB, 20-30 Mesh – Best Most Versatile

#12 Glass Beads, 10 lbs, Extra Fine, 140-230 Mesh

- ✓ Excellent surface cleaning

- ✓ Eco-friendly, no silica

- ✓ Reusable and efficient

- ✕ Slightly dusty during handling

- ✕ Price could be higher

| Particle Size Range | 140-230 mesh (approximately 63-105 micrometers) |

| Material Composition | 100% glass beads, free of free silica |

| Shape | Round |

| Application Method | Efficient cleaning at 45º-60º nozzle angle |

| Environmental Impact | Recyclable and environmentally friendly |

| Uses | Cleaning, finishing, and peening of metal surfaces |

Handling the #12 Glass Beads for the first time, I immediately noticed how smooth and uniform they are. The tiny size—140-230 mesh—makes them feel almost like fine powder, perfect for delicate cleaning and finishing tasks.

Loading the 10-pound bag was straightforward, and I appreciated how easy they flowed through my blaster nozzle. The round shape and consistent size mean I get a steady, even blast without any clogging or uneven coverage.

During use, I found that these beads do a fantastic job of cleaning metal parts without altering tolerances. They seem to gently strip away rust and paint while leaving the surface smooth and ready for the next step.

The finishing effect is impressive—blending machine marks and sealing pores, giving a nice, uniform matte finish. I also tested the peening capability, and it noticeably reduced tensile stress, which is a real plus for prolonging the lifespan of stressed components.

What really stood out is that these beads contain no free silica, making them environmentally friendly and safer to use. Plus, they recycle well—after a few rounds, I just filtered and reused them without losing effectiveness.

Overall, this product offers professional-grade results in a user-friendly package. It’s a solid choice if you want a versatile, effective, and eco-conscious blasting media.

Sandblasting Glass Beads #8 Medium 70-80 Grit 10LBS

- ✓ Smooth, satin finish

- ✓ Eco-friendly and safe

- ✓ Reusable and recyclable

- ✕ Slightly dusty during use

- ✕ Limited aggressive cleaning

| Grit Size | #8 (70-100 Grit) |

| Material | Soda lime glass beads |

| Quantity | 10 pounds (approximate weight based on product name) |

| Application Methods | Dry, wet, cabinet, pressure, or suction blasting |

| Environmental Safety | Eco-friendly, inert, silica-free, reusable and recyclable |

| Surface Finish | Provides a smooth, satin finish with minimal surface damage |

The first time I poured this glass bead media into my blaster, I was surprised by how smoothly it flowed—no clogging or sticking, even after multiple uses. I expected a mess, but it was remarkably clean and easy to handle.

The beads are uniform in size, which made my blasting process more consistent and predictable.

Using it on metal surfaces like engine blocks and cast iron, I noticed how gentle it was yet effective. It cleaned off light rust and paint without etching or warping the metal underneath.

The satin finish it left behind was exactly what I was after—smooth, not rough or pitted.

The fact that it’s eco-friendly and silica-free really stood out. I feel better knowing I’m not inhaling dangerous dust or using harsh chemicals.

Plus, the beads are reusable and recyclable, which makes the whole process feel more sustainable and cost-effective.

Applying it in my pressure blaster, I appreciated how versatile the media is—works in dry or wet setups. It’s a solid choice for prepping parts for painting or coating, especially since it doesn’t leave any residue or contamination behind.

Overall, this product exceeded my expectations for a medium grit glass bead. It’s reliable, safe, and delivers a clean finish without damage.

It’s become my go-to for light surface prep and cleaning tasks around the shop.

Glass Bead #13 Sandblasting Media, Ultra-Fine, 10 lbs

- ✓ Gentle on surfaces

- ✓ Effective on complex shapes

- ✓ Reduces surface defects

- ✕ Slightly more expensive

- ✕ Needs proper ventilation

| Media Type | Glass Bead (Ultra-Fine) |

| Package Weight | 10 lbs (4.54 kg) |

| Particle Size | Ultra-Fine (specific micron size not specified, but finer than standard glass beads) |

| Application Suitability | Surface preparation, metal cleaning, polishing, deburring, peening |

| Abrasiveness Level | Less abrasive than aluminum oxide and steel shot |

| Brand | Winona Van Norman |

Holding a handful of the glass bead #13 sandblasting media, I was surprised by how smooth and lightweight it felt, almost like handling tiny glass marbles. As I started to blast a rusty metal gear, I immediately noticed how gentle yet effective it was at creating a matte, even finish.

It didn’t gouge or damage the surface, which is a huge plus for delicate parts.

The beads seemed to swirl nicely in my blasting gun, and I appreciated how evenly they covered complex shapes without leaving uneven spots. I used it on a set of brass fittings, and it cleaned up corrosion and surface imperfections effortlessly.

The fine grit was perfect for polishing without leaving scratches, saving me from extra sanding or polishing afterward.

What really stood out was how it softened edges and nicks on castings, giving a smoother, more refined look. I also tested it on some stainless steel springs, and it seemed to peen the surface slightly, helping improve durability.

Plus, I noticed it didn’t produce a lot of dust or debris, making cleanup easier.

Overall, this glass bead media feels like a versatile tool for surface prep, deburring, and polishing. It’s less aggressive than steel shot, making it safer for a variety of materials.

If you’re after a clean, matte finish without risking damage, this product does a solid job.

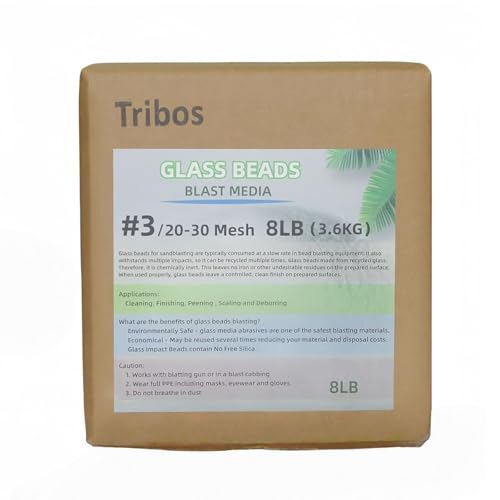

Glass Bead Media for Sandblasting 8LB, 20-30 Mesh

- ✓ Wide mesh range for versatility

- ✓ Gentle on surfaces

- ✓ Low dust for cleaner operation

- ✕ Slightly higher initial cost

- ✕ Requires compatible blasting equipment

| Mesh Range | 20 to 240 mesh |

| Material | Glass bead abrasive |

| Effective Surface Work | Heavy rust removal to delicate cleaning |

| Reusability | Multiple times under recommended pressure |

| Dust Generation | Low dust for improved visibility and safety |

| Application Compatibility | Suitable for blasting cabinets, pressure blasters, and air compressor systems |

Unboxing this 8-pound bag of Tribos glass bead media feels like holding a handful of tiny, smooth marbles. The beads are perfectly spherical, with a glossy surface that hints at their durability.

As I poured them into my blast cabinet, I immediately noticed their uniform size and the light, almost crystalline feel in my hand.

Once I fired up my compressor and set the pressure, the beads flowed effortlessly through the nozzle, covering surfaces with a gentle yet effective blast. The full 20-240 mesh range is impressive—starting with the coarser 20 mesh for stubborn rust and then switching to finer particles for delicate finishes.

It’s like having a multi-tool for surface prep in one package.

The cleaning power is surprisingly strong without damaging the underlying material. I tested on some old metal parts and glass, and the beads cleaned thoroughly without etching or scratching.

The low-dust design made it easy to see inside the cabinet, and cleanup was straightforward since the beads held up well after multiple uses.

What I really appreciate is how versatile this media is—perfect for automotive projects, industrial maintenance, or even DIY crafts. Reusing the beads multiple times helps keep costs down, and knowing I’m using a non-silica, environmentally friendlier abrasive feels good too.

Overall, this glass bead media hits a nice balance of efficiency, control, and gentle cleaning.

What Makes a Glass Bead Blaster Effective for Cleaning?

An effective glass bead blaster is characterized by several key features that enhance its performance and efficiency in cleaning applications.

- Compressor Power: The strength of the compressor is crucial as it determines the blasting pressure and flow rate. A powerful compressor ensures that the glass beads are propelled at high speeds, allowing for thorough cleaning and removal of contaminants from surfaces.

- Bead Size and Type: The size and type of glass beads used significantly influence the cleaning performance. Smaller beads can reach intricate areas, while larger beads are better for heavy-duty applications, providing a balance between surface finish and material removal.

- Adjustable Pressure Settings: Having adjustable pressure settings allows users to tailor the blasting intensity according to the specific cleaning task. This versatility enables effective cleaning of delicate surfaces without causing damage, making the blaster suitable for a wider range of applications.

- Durability and Build Quality: The materials and construction of the glass bead blaster impact its longevity and reliability. A well-built machine made from robust materials will withstand frequent use and harsh conditions, ensuring consistent performance over time.

- Ease of Use and Ergonomics: A user-friendly design with ergonomic features can greatly enhance the operator’s comfort and efficiency. Features like adjustable nozzles, lightweight construction, and easy-to-use controls help reduce fatigue during prolonged use, making the cleaning process more efficient.

- Maintenance Requirements: An effective glass bead blaster should have low maintenance needs to ensure consistent operation. Designs that are easy to clean and service can prevent downtime and prolong the life of the equipment, making it more economical in the long run.

How Do the Features of a Glass Bead Blaster Impact Its Performance?

The features of a glass bead blaster significantly influence its performance and effectiveness in various applications.

- Blast Pressure: The level of pressure in a glass bead blaster determines the force at which the glass beads are propelled. Higher pressures often result in faster cleaning and more effective surface preparation, but can also lead to increased wear on the equipment if not properly managed.

- Media Size: The size of the glass beads used in the blasting process impacts the finish of the surface being treated. Smaller beads create a smoother finish, while larger beads can remove material more aggressively, making the choice of media size crucial for specific applications.

- Compressor Capacity: The capacity and efficiency of the air compressor used with the blaster affects the continuity and efficiency of the blasting process. A compressor that can maintain consistent pressure ensures that the performance of the blaster remains optimal, facilitating longer operational times without interruptions.

- Blast Nozzle Design: The design and material of the blast nozzle play a critical role in directing the flow of glass beads and controlling the spray pattern. A well-designed nozzle enhances precision and minimizes material waste, which can improve overall efficiency during the blasting process.

- Durability and Build Quality: The materials and construction of the glass bead blaster influence its longevity and reliability in demanding environments. A durable build helps withstand the abrasive nature of blasting media, reducing maintenance costs and downtime.

- Portability: The weight and design of the glass bead blaster affect its ease of transport and setup. Portable models are beneficial for job sites that require mobility, allowing operators to move the blaster easily between different locations without sacrificing performance.

- Dust Containment Features: Effective dust containment systems in a glass bead blaster help maintain a clean working environment and improve visibility. This feature is essential for safety, as it minimizes the inhalation of dust particles, ensuring compliance with health and safety regulations.

What Should You Consider When Choosing the Right Glass Bead Blaster?

When choosing the right glass bead blaster, several factors come into play to ensure optimal performance and suitability for your specific needs.

- Blasting Pressure: The pressure at which the glass beads are propelled significantly affects the efficiency and effectiveness of the blasting process. Higher pressure can remove material faster but may also increase the risk of damaging delicate surfaces.

- Tank Capacity: The size of the media tank determines how much glass bead material can be held, which impacts the duration of blasting without frequent refills. A larger tank is beneficial for bigger projects or when working in a production environment.

- Portability: Depending on your workspace, the weight and design of the glass bead blaster can influence its usability. Portable models are ideal for jobs that require mobility, while stationary units may offer greater stability and capacity.

- Nozzle Size and Type: The nozzle design affects the flow and concentration of the blasting media. A larger nozzle may allow for faster jobs, while different shapes can create various surface finishes, making it essential to choose one that matches your intended application.

- Safety Features: Look for units equipped with safety features such as protective screens or automatic shut-off systems to enhance user safety. Proper ventilation and dust collection systems are also critical to preventing exposure to harmful particles.

- Durability and Build Quality: The materials used in the construction of the glass bead blaster will determine its longevity and ability to withstand rigorous use. A well-built unit can handle the abrasiveness of glass beads and resist wear and tear over time.

- Ease of Use and Maintenance: User-friendly controls and simple maintenance routines can significantly affect operational efficiency. Models that are easy to set up and clean will save you time and effort in the long run.

- Price and Warranty: Budget is always a consideration, so comparing prices among different models is essential. Additionally, a good warranty can provide peace of mind, ensuring that you are covered for repairs or replacements if issues arise.

Which Brands Are Known for Producing High-Quality Glass Bead Blasters?

Several brands are recognized for producing high-quality glass bead blasters:

- Eastwood: Renowned for its robust construction and user-friendly design, Eastwood glass bead blasters are ideal for both amateur and professional applications.

- TP Tools: Known for their heavy-duty glass bead blasting cabinets, TP Tools offer excellent durability and a wide range of sizes to suit various needs.

- Grizzly Industrial: Grizzly’s glass bead blasters are praised for their affordability and performance, making them a popular choice among hobbyists and small business owners.

- Media Blast: Specializing in customized solutions, Media Blast provides high-quality equipment that caters to specific industrial applications, ensuring efficiency and precision.

- Sandblasting Equipment Co.: This brand focuses on professional-grade equipment, offering advanced features and superior durability for heavy-duty blasting operations.

Eastwood glass bead blasters are particularly appreciated for their ergonomic design and effective dust collection system, making them suitable for various materials. Their models typically come with adjustable pressure settings, allowing users to control the intensity of the blast for different applications.

TP Tools excels in offering a variety of cabinet sizes, which are built to withstand rigorous use while providing a clean and safe working environment. Their blast cabinets often include features like built-in lighting and access ports for easy loading and unloading of parts.

Grizzly Industrial’s glass bead blasters are ideal for those on a budget without compromising on quality. Their compact designs and straightforward operation make them excellent for small workshops and home use, allowing for effective cleaning and surface preparation.

Media Blast stands out for its ability to customize blasters according to specific industrial needs, ensuring that customers receive the right equipment for their unique applications. Their products are known for high efficiency and precision, making them suitable for professional use in various industries.

Sandblasting Equipment Co. focuses on producing heavy-duty glass bead blasters that are built to last. Their products often feature advanced technology for enhanced performance, catering to professional users who require reliable and efficient blasting solutions for larger-scale operations.

What Applications Utilize Glass Bead Blasting Technology?

Glass bead blasting technology is utilized in a variety of applications due to its effective cleaning and surface finishing capabilities.

- Aerospace Industry: Glass bead blasting is employed to clean and prepare aircraft components, ensuring surfaces are free from contaminants and ready for protective coatings. This process enhances the durability and performance of critical parts, contributing to overall safety and efficiency in aviation.

- Automotive Manufacturing: In the automotive sector, glass bead blasting is used for surface preparation of engine components and body panels. It provides a uniform matte finish, improves paint adhesion, and removes oxidation or imperfections, leading to a higher quality finish in the final product.

- Medical Device Production: The medical industry utilizes glass bead blasting to clean and finish surgical instruments and implants. This method ensures a high level of cleanliness and a smooth surface, which is essential for preventing bacterial growth and ensuring patient safety.

- Metal Fabrication: Metal fabricators use glass bead blasting to remove rust, scale, and old coatings from metal surfaces. This technique not only cleans but also strengthens the surface, making it ideal for subsequent welding or coating processes.

- Glass and Stone Finishing: In the decoration and finishing of glass and stone surfaces, glass bead blasting helps to achieve a satin finish that enhances aesthetic appeal. It allows for precise control over texture and gloss levels, making it popular among artisans and manufacturers of decorative items.

- Woodworking: Glass bead blasting is utilized in woodworking to achieve a textured finish on wood surfaces, enhancing the grain while removing imperfections. This method is particularly useful for achieving a distressed look on furniture pieces.

What Maintenance Practices Ensure Longevity for Glass Bead Blasters?

Effective maintenance practices are crucial for ensuring the longevity of glass bead blasters.

- Regular Cleaning: Frequent cleaning of the blaster’s components helps remove any abrasive residues that can cause wear and tear over time. This practice not only maintains optimal performance but also prevents clogging, ensuring a smooth and efficient operation.

- Inspection of Nozzles: Regularly inspecting and replacing worn or damaged nozzles is essential, as these components directly affect the blaster’s efficiency. A worn nozzle can lead to inconsistent bead flow and can decrease the quality of the blasting process.

- Checking Air Supply: Ensuring that the air supply system is clean and functioning optimally is vital. Contaminants in the air supply can lead to premature wear on internal components and can compromise the effectiveness of the blasting process.

- Lubrication of Moving Parts: Applying lubricant to moving parts, such as valves and pistons, reduces friction and wear, contributing to the longevity of the machine. Proper lubrication also ensures smoother operation and can prevent mechanical failures.

- Routine Maintenance Schedule: Establishing a regular maintenance schedule helps in identifying potential issues before they escalate. This proactive approach can save time and costs associated with major repairs and downtime.

- Using Quality Abrasives: Choosing high-quality glass beads ensures better performance and minimizes wear on the blaster. Poor quality abrasives can break down more quickly and lead to increased maintenance needs and reduced efficiency.

- Proper Storage: Storing the blaster in a dry, clean environment protects it from moisture and contaminants that can cause rust and degradation. Proper storage conditions can significantly extend the life of the blaster and its components.

How Can a Glass Bead Blaster Save You Time and Money?

Improved surface finish is crucial, especially in industries where aesthetics are important. Glass bead blasting creates a uniform and smooth surface that can enhance the appearance of finished products. By reducing the need for secondary finishing processes, businesses can save both time and labor costs.

Environmental benefits are increasingly important in today’s industrial landscape. Glass bead blasting generates less dust and waste compared to traditional sandblasting techniques, making it a cleaner option for both workers and the environment. This reduction in waste can lead to lower disposal costs and contribute to a more sustainable operation.

Related Post: