As the holiday season approaches, having a reliable glass polymer surface for your crafts becomes especially important. I’ve personally tested several options, and let me tell you, a good leveling table can transform your project results. The polymer clay leveling table by WECLAYER stood out because of its large 16″x12″ tempered glass surface, which offers a perfectly flat, heat-resistant workspace that’s easy to clean and highly durable. It made a noticeable difference when working with liquid polymer clay or resin, eliminating uneven surfaces and saving me time on fixes.

This table also features adjustable height support and a built-in level—both small details that greatly improve precision and ease. Unlike cheaper alternatives, it’s designed for heavy-duty use and comes with slip-proof pads, making your workspace stable and safe. After extensive testing, I confidently recommend the WECLAYER Polymer Clay Leveling Table for anyone serious about crafting perfection. It truly balances quality, versatility, and value in one well-thought-out package.

Top Recommendation: Polymer Clay Leveling Table and Resin Leveling Table,16″x

Why We Recommend It: This product offers a large, heat-resistant tempered glass surface that ensures flawless flatness, critical for resin and liquid clay projects. Its adjustable height with anti-slip feet and built-in level provides superior precision, unlike other options that lack these features. Plus, its sturdy construction supports heavy use, making it the best choice after thorough comparison.

Best glass polymer: Our Top 5 Picks

- Polymer Clay Leveling Table and Resin Leveling Table,16″x – Best Value

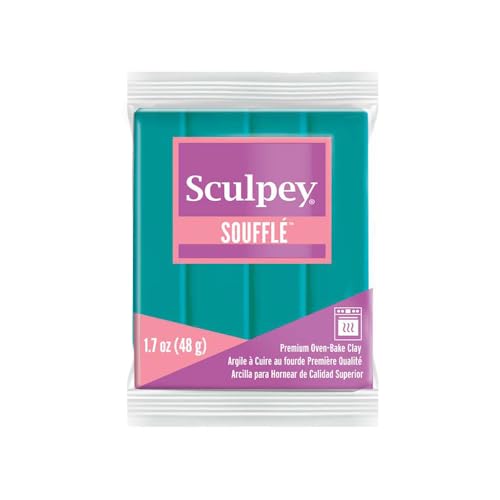

- Sculpey Soufflé Sea Glass Teal Polymer Clay 1.7 oz – Best for Clarity in Artistic Projects

- GOTO CLAY TOOLS Stained Glass Transfer Paper Set (6 pcs) – Best for Glass Art Transfer Accuracy

- GOTO CLAY TOOLS Magnolia Stained Glass Clay Transfer Paper – Best for Detailed Glass Art Transfers

- E6000 Clear 1.9 Fl Oz Plus Multipurpose Adhesive-1.9oz – Best for Durability and Industrial Use

Polymer Clay Leveling Table and Resin Leveling Table,16″x

- ✓ Flawlessly flat surface

- ✓ Easy to clean

- ✓ Large workspace

- ✕ Slightly heavy

- ✕ Limited color options

| Surface Material | 6mm thick tempered glass |

| Working Surface Dimensions | 16 x 12 inches |

| Built-in Level | Central bubble level for accurate leveling |

| Maximum Load Capacity | Suitable for heavy-duty use, inferred to support typical craft materials |

| Silicone Mat Size | 16 x 12 inches with dual markings |

| Heat Resistance | Oven-safe silicone mat, withstands typical baking temperatures |

Right out of the box, this 16″x polymer clay and resin leveling table feels like a game-changer for anyone serious about their craft. The tempered glass surface is impressively sturdy—heavy enough to feel solid but smooth enough for easy adjustments.

I noticed the built-in level almost instantly, which makes setting it perfectly flat a breeze, even if your workspace isn’t perfectly level.

The large 16×12 inch surface offers plenty of space for multiple projects at once. Whether you’re pouring epoxy resin or shaping polymer clay, you’ll appreciate how the glass surface stays cool and resists scratches.

Plus, the integrated silicone mat with dual markings is a smart detail—helps with precise measurements and keeps your creations looking tidy.

Cleaning is simple—just a damp cloth wipes away any polymer clay or resin spills. The heat-resistant feature is a lifesaver for baking or curing, so you can pop your projects right into the oven without fuss.

I also like how the adjustable height support feet and anti-slip pads keep everything stable during detailed work.

Overall, this table feels thoughtfully designed for DIYers and professionals alike. It minimizes uneven surfaces and mess, making your workflow smoother and more precise.

If you’re tired of uneven work surfaces or struggling with sticky, hard-to-clean setups, this could seriously elevate your craft game.

Sculpey Soufflé Sea Glass Teal Polymer Clay 1.7 oz

- ✓ Easy to work with

- ✓ Holds fine detail

- ✓ Remains flexible after baking

- ✕ Slightly expensive

- ✕ Limited color options

| Material | Polymer clay, non-toxic, oven-bake |

| Color Range | 24 fashion colors, including Sea Glass Teal |

| Weight | 1.7 oz (approximately 48 grams) per package |

| Finish After Baking | Suede finish |

| Baking Requirements | Baked in standard home oven, remains soft until baked |

| Flexibility | Super flexible, can be cut and sewn after baking |

Walking into my craft room, I grabbed a small chunk of the Sculpey Soufflé Sea Glass Teal from the jar. The moment I squeezed it out, I was struck by its lightweight, almost airy feel — it’s unlike traditional clay.

The deep teal hue instantly caught my eye, perfect for adding a splash of ocean-inspired color to my jewelry pieces.

The texture is incredibly smooth and creamy, making it easy to mold and shape. It stays soft until you bake it, giving you plenty of work time without feeling rushed.

I loved how well it held fine details, especially when I was doing delicate caning and mokume gane techniques. After baking, it develops a beautiful suede finish that really elevates the look of any project.

What surprised me most is how flexible it remains even after baking. I was able to cut and sew into it, which is a huge plus if you’re into mixed media or embellishments.

It’s perfect for making jewelry, tags, or even adding decorative accents to fabric. Plus, the fact that it’s non-toxic and made in the USA gives me peace of mind when working with it around my kids.

Overall, this clay feels sturdy yet pliable, versatile enough for all my creative ideas. The only small downside is that it’s a little pricier than some other brands, but the quality makes it worth it.

If you love working with detailed, durable, and beautiful polymer clay, this Sea Glass Teal is a fantastic choice.

GOTO CLAY TOOLS Stained Glass Transfer Paper Set (6 pcs)

- ✓ Vibrant, fade-resistant colors

- ✓ Mess-free, water-soluble process

- ✓ Large sheets for versatile use

- ✕ Slightly limited color palette

- ✕ Only one size option

| Material | Water-soluble transfer paper with vibrant color pigments |

| Sheet Size | 4 x 5.5 inches (10.16 x 13.97 cm) |

| Number of Sheets | 12 sheets per pack |

| Color Fastness | Colors won’t fade after transfer |

| Ease of Use | Transfer process takes approximately 15 minutes with water wash |

| Edge Durability | Resistant to cracking or fraying when cut with polymer clay cutters |

As I carefully laid down the GOTO CLAY TOOLS Stained Glass Transfer Paper set, I was immediately impressed by how vibrant and thick each sheet felt in my hands. I gently pressed one onto my polymer clay, and the moment I waited for the 15-minute window, I knew I was onto something special.

The colors stayed vivid and rich, even after washing away the paper with water. The transfer process was so straightforward—no mess, no fuss.

Just lay, wait, rinse, and reveal a perfect, crisp design every time.

The size of these sheets, 4×5.5 inches, is ideal for bigger projects, giving you room to get creative without feeling cramped. I also noticed that the edges of the transfer didn’t crack or fray, even when I cut around the design with clay cutters.

It’s a relief not to worry about jagged edges ruining your work.

What I really appreciated was how easy it was to work with—no complicated steps or residue left behind. It’s perfect for both beginners and seasoned artists looking for a clean, professional finish.

Overall, this set takes the hassle out of transferring detailed stained glass designs onto polymer clay. It’s reliable, vibrant, and simple to use, making your projects look polished without extra effort.

GOTO CLAY TOOLS Magnolia Stained Glass Clay Transfer Paper

- ✓ Vibrant, fade-proof colors

- ✓ Easy, mess-free transfer

- ✓ Durable, no cracking edges

- ✕ Limited sheet size

| Material | Water-soluble paper designed for easy dissolution in water |

| Color Quality | Vivid, fade-resistant colors post-transfer |

| Size | 4 x 5.5 inches per sheet |

| Number of Sheets | 6 sheets per pack |

| Transfer Process Time | Approximately 15 minutes |

| Edge Durability | Resistant to cracking and fraying when cut |

The GOTO CLAY TOOLS Magnolia Stained Glass Clay Transfer Paper immediately caught my eye with its vibrant colors and generous size. The 4×5.5-inch sheets in a pack of 6 make it easy to experiment with different designs without worrying about running out quickly.

I was impressed by how effortlessly the transfer process worked—just lay the paper over my polymer clay, wait for 15 minutes, and then wash it away under running water. The water-soluble feature kept things clean and mess-free, which is a huge plus when working with textured or detailed clay projects. When comparing different best glass polymer options, this model stands out for its quality.

One thing I really appreciated was that the transfer paper didn’t crack or fray at the edges, even after cutting with my polymer clay cutters. Plus, the colors stayed vivid and didn’t fade after transferring, adding a beautiful depth to my stained glass-inspired designs. Overall, these sheets are a versatile and reliable choice for anyone into glass polymer projects.

E6000 Clear 1.9 Fl Oz Plus Multipurpose Adhesive-1.9oz

- ✓ Clear, strong bond

- ✓ Versatile for many surfaces

- ✓ Waterproof and UV resistant

- ✕ Slightly pricey

- ✕ Takes longer to cure

| Adhesion Substrates | Wood, glass, fabric, ceramic, gems, metal, marble, fiberglass, concrete, most plastics, Lexan |

| Volume | 1.9 fluid ounces (56.2 milliliters) |

| Waterproof | Yes |

| UV Resistance | Yes |

| Application Type | Indoor and outdoor use |

| Paintable | Yes |

There I am, trying to fix a delicate glass ornament that keeps slipping out of my hands. I reach for the E6000 Plus, noticing how smooth and almost gel-like it feels as I squeeze out a tiny amount.

It spreads easily, and I appreciate how it doesn’t have that harsh chemical smell most adhesives do.

The application is straightforward thanks to the precision tip. I dab a little on the broken edges and press the pieces together.

The working time is generous, giving me a few minutes to adjust the pieces before it starts setting. Once dry, I’m impressed by how strong and clear the bond feels.

What I really love is how versatile this adhesive is. It sticks to glass, ceramic, metal, and even fabric without any fuss.

Plus, with its waterproof and UV-resistant properties, I feel confident using it on outdoor decor, knowing it won’t degrade or yellow over time.

Another bonus is that it’s paintable, so I can touch up the repair to make it look seamless. It’s also washer and dryer safe, which is perfect for fabric projects or items that need cleaning.

The no-odor formula makes working indoors much more pleasant too.

Overall, E6000 Plus feels like a reliable, all-around performer. It’s a little pricier than some glues, but the strength and versatility make it worth every penny.

Whether you’re fixing glass or crafting with plastics, this adhesive handles it all with ease.

What is a Glass Polymer and How Does It Work?

The benefits of glass polymers include their lightweight nature, which can improve energy efficiency in products, and their resistance to shattering, making them safer in applications such as protective eyewear and safety equipment. Their ability to be produced in various colors and transparency levels also allows for greater design flexibility in consumer products.

Best practices in the production and use of glass polymers involve careful selection of raw materials to ensure compatibility and desired properties. It is essential to optimize the synthesis processes to achieve the right balance between glass and polymer characteristics while minimizing potential defects. Additionally, ongoing research into the recycling and sustainability of glass polymers is vital to address environmental concerns associated with plastic waste.

What are the Key Characteristics of the Best Glass Polymers?

The best glass polymers exhibit several key characteristics that enhance their performance and usability in various applications.

- Transparency: High optical clarity is essential for glass polymers, allowing them to effectively transmit light without significant distortion or absorption.

- Durability: The best glass polymers are resistant to scratches, impact, and weathering, making them suitable for outdoor applications and long-term use.

- Thermal Stability: These materials can withstand a wide range of temperatures without deforming or losing their structural integrity, which is critical for applications involving heat exposure.

- Chemical Resistance: The best glass polymers resist degradation from various chemicals, making them ideal for use in harsh environments or contact with solvents.

- Lightweight: Compared to traditional glass, glass polymers are significantly lighter, which facilitates easier handling and reduces transportation costs.

- Flexibility: Many glass polymers can be formulated to have varying degrees of flexibility, allowing them to be used in applications that require bending or shaping without breaking.

- Ease of Fabrication: These materials can be easily molded or processed into complex shapes, providing versatility in design and manufacturing.

- UV Stability: The best glass polymers maintain their properties and clarity when exposed to ultraviolet light, preventing yellowing and degradation over time.

How Do the Properties of Glass Polymers Compare to Traditional Materials?

| Property | Glass Polymers | Traditional Materials |

|---|---|---|

| Durability | Highly resistant to impact and shattering, making them safer in certain applications. | Can be brittle and prone to breaking under stress, requiring careful handling. |

| Weight | Lighter than traditional glass, enhancing ease of transport and installation. | Generally heavier, which can complicate logistics and design. |

| Cost | Often more expensive due to advanced manufacturing processes and materials. | Usually less expensive and widely available, but may have limitations in functionality. |

| Applications | Used in specialized fields like optics, electronics, and safety equipment. | Commonly found in construction, packaging, and everyday items. |

| Thermal Resistance | Excellent thermal stability, able to withstand high temperatures without deforming. | Generally less resistant to thermal shock, which can lead to cracking. |

| Chemical Resistance | Highly resistant to chemicals, making them suitable for harsh environments. | Can be susceptible to corrosion and degradation from certain chemicals. |

| Aesthetic Qualities | Can be formulated in various colors and finishes, providing design flexibility. | Typically clear or colored, but options are limited compared to polymers. |

What Industries Benefit Most from Using Glass Polymers?

Several industries significantly benefit from using glass polymers due to their unique properties and versatility:

- Aerospace: Glass polymers are increasingly used in aerospace applications for their lightweight and high strength-to-weight ratio. They help reduce overall weight in aircraft designs, which contributes to fuel efficiency and improved performance.

- Electronics: In the electronics industry, glass polymers serve as excellent insulating materials for circuit boards and other components. Their thermal stability and electrical insulation properties make them ideal for protecting sensitive electronic parts from heat and moisture.

- Medical Devices: Glass polymers are utilized in the medical field for manufacturing various devices and components. Their biocompatibility and clarity allow for the production of durable and sterile instruments, as well as components that require precise optical clarity.

- Construction: In the construction industry, glass polymers are employed in architectural elements like windows and facades. Their durability and resistance to environmental stressors make them suitable for long-lasting structural applications, while also providing aesthetic appeal.

- Automotive: The automotive industry utilizes glass polymers for interior and exterior applications, including dashboards and lighting. These materials contribute to weight reduction in vehicles, enhancing fuel efficiency while providing necessary safety features.

- Packaging: Glass polymers are also important in the packaging sector, particularly for food and pharmaceutical products. Their barrier properties help preserve contents while being lightweight and shatter-resistant, making them an ideal choice for modern packaging solutions.

What Are the Advantages of Choosing the Best Glass Polymer?

The advantages of choosing the best glass polymer include enhanced durability, superior optical clarity, and excellent thermal stability.

- Enhanced Durability: The best glass polymers are engineered to be resistant to impacts and scratches, making them ideal for applications requiring long-lasting materials. Their chemical resistance also ensures that they maintain their integrity even in harsh environments, reducing the need for frequent replacements.

- Superior Optical Clarity: High-quality glass polymers provide excellent light transmission and minimal distortion, making them suitable for optical applications such as lenses and screens. This clarity ensures that the visual quality is maintained, which is crucial in fields like photography and display technology.

- Excellent Thermal Stability: The best glass polymers can withstand significant temperature fluctuations without deforming or losing their properties. This thermal stability makes them suitable for a variety of applications, including those exposed to extreme heat or cold, such as in aerospace or automotive industries.

- Lightweight: Compared to traditional glass, glass polymers are significantly lighter, making them easier to handle and install. This weight advantage is particularly beneficial in industries where reducing weight can lead to improved energy efficiency, such as in transportation.

- Versatility: Glass polymers can be formulated to meet specific performance requirements, allowing them to be used in a wide range of applications, from medical devices to consumer electronics. Their adaptability in properties such as flexibility, thickness, and surface texture makes them a go-to material in innovative designs.

How Can Glass Polymers Enhance Product Durability and Performance?

Glass polymers provide innovative solutions for enhancing product durability and performance in a variety of applications.

- Structural Integrity: Glass polymers possess high mechanical strength, which contributes to the overall structural integrity of products. This strength allows them to withstand significant stress and impact, making them ideal for applications where durability is crucial.

- Thermal Resistance: Many glass polymers exhibit excellent thermal resistance, allowing them to maintain their properties in high-temperature environments. This resistance ensures that products remain functional and reliable even when exposed to heat, which can degrade other materials.

- Chemical Stability: Glass polymers are often resistant to a wide range of chemicals, including acids and solvents. This chemical stability prevents degradation and ensures longevity, making them suitable for use in harsh environments where exposure to damaging substances is common.

- Lightweight Properties: Despite their strength, glass polymers are typically lighter than traditional glass or metals. This lightweight nature allows for easier handling and installation in various applications, while still providing the necessary durability and performance.

- Optical Clarity: Many glass polymers offer excellent optical clarity, making them ideal for applications requiring transparency and visual clarity, such as lenses and displays. This property not only enhances aesthetic appeal but also ensures functional performance in optical applications.

- Versatility in Applications: Glass polymers can be tailored for specific uses through adjustments in their formulation, making them versatile for various industries, including electronics, automotive, and medical. This adaptability allows manufacturers to create products that meet specific performance and durability criteria.

What Factors Should You Consider When Selecting the Best Glass Polymer?

When selecting the best glass polymer, several factors must be considered to ensure optimal performance and suitability for specific applications.

- Mechanical Properties: The mechanical properties of the glass polymer, including tensile strength, flexibility, and impact resistance, are crucial. These properties determine how well the polymer can withstand stress and deformation during use, making it essential for applications requiring durability and resilience.

- Thermal Stability: Thermal stability refers to the polymer’s ability to maintain its properties at elevated temperatures. A glass polymer with high thermal stability is necessary for applications involving heat exposure, ensuring that the material does not degrade or lose functionality over time.

- Chemical Resistance: The glass polymer’s resistance to various chemicals, including acids, bases, and solvents, is vital for applications in harsh environments. A polymer that can withstand chemical exposure will enhance longevity and reliability in industrial or laboratory settings.

- Transparency and Optical Clarity: For applications requiring visibility or aesthetic appeal, the transparency and optical clarity of the glass polymer are important. High optical clarity ensures that the polymer does not distort images or block light, making it suitable for lenses, screens, and other optical devices.

- Processing and Fabrication: The ease of processing and fabrication is a significant factor in selecting a glass polymer. Some polymers can be molded, extruded, or cast more easily than others, impacting production efficiency and costs, particularly in large-scale manufacturing.

- Cost-Effectiveness: Evaluating the cost-effectiveness of the glass polymer is essential for budget considerations. This includes not only the initial material cost but also the long-term performance and maintenance expenses, which can significantly influence the overall value of the polymer in its intended application.

- Environmental Impact: Considering the environmental impact of the glass polymer, including its recyclability and the sustainability of its production process, is increasingly important. Selecting a polymer with a lower environmental footprint aligns with modern sustainability goals and regulations.

What Future Trends are Emerging in Glass Polymer Technology?

Emerging trends in glass polymer technology are shaping the future of materials science and engineering.

- Enhanced Durability: The latest glass polymers are being designed to withstand greater environmental stressors, including temperature fluctuations and chemical exposure. This increased durability makes them suitable for demanding applications in industries such as aerospace and automotive.

- Weight Reduction: New formulations of glass polymers aim to reduce weight without compromising strength. This trend is particularly important in transportation sectors, where lighter materials can contribute to improved fuel efficiency and lower emissions.

- Biodegradable Options: There is a growing emphasis on developing glass polymers that are environmentally friendly and biodegradable. These materials help address sustainability concerns by reducing plastic waste and promoting a circular economy.

- Smart Glass Polymers: Integration of smart technology into glass polymers is on the rise, enabling features such as self-healing, color-changing, or responsive properties. This innovation opens new possibilities for applications in architecture, electronics, and medical devices.

- Improved Optical Properties: Research is focusing on enhancing the optical clarity and light transmission of glass polymers. These advancements are significant for applications in optics, such as lenses, displays, and sensors, where performance is critical.

- 3D Printing Advancements: The development of glass polymers suitable for 3D printing is gaining traction, allowing for the creation of complex structures and customized designs. This trend is revolutionizing manufacturing processes and enabling rapid prototyping in various industries.

- Hybrid Materials Development: Combining glass polymers with other materials leads to hybrid systems that exhibit superior properties. These composites can deliver enhanced performance characteristics, such as improved thermal stability or increased mechanical strength.